In today's competitive business landscape, maintaining quality is paramount for success. Poor quality can lead to dissatisfied customers, increased costs, and a damaged reputation of the brand. To ensure consistent quality, businesses employ various techniques, and one such powerful tool is Statistical Process Control (SPC). Statistical Process Control (SPC) enables organizations to harness data effectively to monitor and improve processes, ultimately enhancing product or service quality.

In this blog, we'll delve into the history of Statistical Process Control (SPC), its key principles, benefits, and how it contributes to quality assurance.

History of Statistical Process Control (SPC):

Statistical Process Control (SPC) traces its origins back to the early 20th century when quality pioneers such as Walter A. Shewhart and W. Edwards Deming laid the groundwork for modern quality management practices.

Who is the founder of Statistical Process Control (SPC):

Shewhart, an American physicist, is widely regarded as the father of Statistical Process Control (SPC) for his ground-breaking work at Bell Telephone Laboratories in the 1920s.

|

| Walter A. Shewhart |

Building upon Shewhart's work, Deming, an American statistician, further popularized the principles of Statistical Process Control (SPC) during the post-World War II era in Japan.

As part of the reconstruction efforts, Deming taught Japanese engineers and managers the importance of statistical quality control and continuous improvement. His teachings laid the foundation for the renowned Japanese quality movement and the emergence of Total Quality Management (TQM) principles.

The advent of computers in the latter half of the 20th century revolutionized Statistical Process Control (SPC), making it more accessible and scalable across industries. With advancements in data collection, analysis, and visualization tools, organizations could implement Statistical Process Control (SPC) more efficiently and derive greater insights from their processes.

You Can Read: Basics of SPC: Understanding Control Charts and Their Types – How to Set Up Control Limits and Track Process Variation

Key Principles of Statistical Process Control (SPC):

1. Data Collection

The first step in Statistical Process Control (SPC) is collecting relevant data from the process under observation. This data may include measurements, counts, or observations related to key process parameters.

2. Data Analysis:

Once collected, the data is analyzed using statistical tools and techniques. Common analyses include calculating measures of central tendency (mean, median), measures of dispersion (standard deviation, range), and plotting data on control charts.

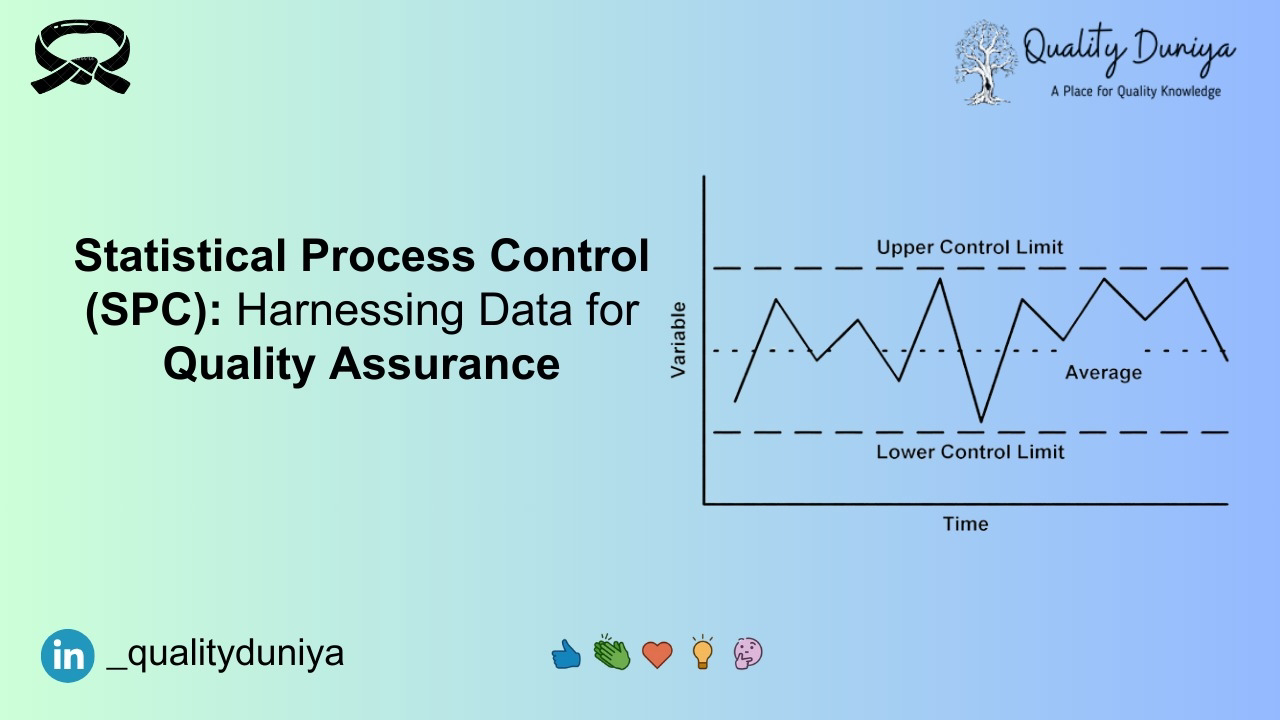

3. Control Charts:

Control charts are graphical tools used in Statistical Process Control (SPC) to monitor process performance over time. These charts display process data along with upper and lower control limits, helping identify variations and trends in the process.

4. Variation Identification:

Statistical Process Control (SPC) distinguishes between common cause variation (inherent to the process) and special cause variation (due to external factors). Understanding these variations is crucial for taking appropriate corrective actions.

5. Continuous Improvement:

Statistical Process Control (SPC) emphasizes the concept of continuous improvement by using data-driven insights to make adjustments and enhancements to the process. It fosters a culture of proactive problem-solving and innovation.

Benefits of Statistical Process Control (SPC):

1. Quality Improvement:

By continuously monitoring process performance, SPC helps identify deviations from standards promptly, allowing for timely corrective actions. This leads to improved product or service quality and customer satisfaction.

2. Cost Reduction:

SPC enables organizations to detect and eliminate defects early in the process, reducing rework, scrap, and warranty costs. By optimizing processes, businesses can also achieve cost savings through increased efficiency.

3. Increased Efficiency:

By understanding process variation and eliminating non-value-added activities, SPC helps streamline operations and improve resource utilization. This leads to enhanced productivity and shorter cycle times.

4. Risk Mitigation:

Statistical Process Control (SPC) assists in identifying potential risks and preventing quality issues before they escalate. Proactively managing process variability reduces the likelihood of costly errors and product recalls.

5. Data-Driven Decision Making:

Statistical Process Control (SPC) provides actionable insights based on empirical evidence rather than intuition or guesswork. This enables informed decision-making at all levels of the organization, leading to better outcomes.

Implementing SPC for Quality Assurance:

1. Define Quality Parameters:

Clearly establish quality standards and specifications for the product or service, including critical-to-quality characteristics.

2. Select Key Metrics:

Identify key performance indicators (KPIs) and process variables to monitor using SPC. These metrics should align with organizational goals and customer requirements.

3. Training and Education:

Train personnel involved in data collection, analysis, and interpretation of SPC principles and techniques. Ensure everyone understands their role in maintaining process quality.

4. Establish Control Limits:

Determine appropriate control limits based on historical data and process capability analysis. These limits serve as benchmarks for evaluating process stability and performance.

5. Monitor and Analyze Data:

Regularly collect and analyze process data using control charts and other statistical tools. Look for patterns, trends, and abnormalities that indicate changes in process behaviour.

6. Take Corrective Actions:

When deviations or out-of-control conditions are detected, take prompt corrective actions to address the root causes and bring the process back into control.

7. Continuously Improve:

Foster a culture of continuous improvement by encouraging feedback, innovation, and collaboration among team members. Use SPC insights to drive ongoing process enhancements.

Conclusion:

Statistical Process Control (SPC) is a powerful tool for quality assurance, enabling organizations to harness data effectively to monitor, control, and improve processes. With its rich history dating back to the pioneering work of Shewhart and Deming, Statistical Process Control (SPC) has evolved into a cornerstone of modern quality management practices.

By embracing Statistical Process Control (SPC) principles and techniques, businesses can achieve higher levels of quality, efficiency, and customer satisfaction. Unlock the full potential of your processes with Statistical Process Control (SPC) and stay ahead in today's competitive marketplace.