A Check Sheet refers to a type of document that is used for recording data at the time and place of the operation of interest. Typically, a blank document is taken to start with, and then it is designed for easy, quick, and effective recording of the required data, which can be either qualitative or quantitative.

This Check Sheet helps in identifying all the possible errors and

has the flexibility to add more sources of error based on practical experience.

These are then used for recording data about the errors, which are eventually

used for analyzing the operational issue.

What is the definition of Check sheet?

A check sheet is a structured, prepared form for collecting

and analyzing data. This is a generic data collection and analysis tool that

can be adapted for a wide variety of purposes and is considered one of the

seven basic quality tools. Check Sheet is also called as defect concentration

diagram

When to use the Check Sheet?

- When data can be observed and collected repeatedly by the same person or at the same location

- When collecting data on the frequency or patterns of events, problems, defects, defect location, defect causes, or similar issues

- When collecting data from a production process

How to use Check Sheet

- Decide what event or problem will be observed. Develop operational definitions.

- Decide when data will be collected and for how long.

- Design the form. Set it up so that data can be recorded simply by making check marks or X's or similar symbols and so that data do not have to be recopied for analysis.

- Label all spaces on the form.

- Test the check sheet for a short trial period to be sure it collects the appropriate data and is easy to use.

- Each time the targeted event or problem occurs, record data on the check sheet.

Types of Check Sheet

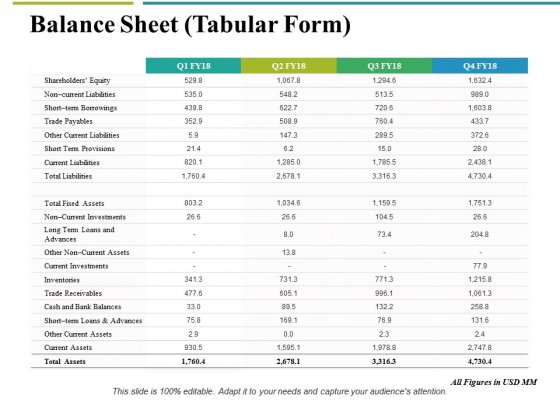

Tabular Sheet: This is usually used for collecting data

about quality issues and determining the frequency of any event—for instance,

the reasons for accidents during laboratory experiments.

|

| Example of Tabular Sheet |

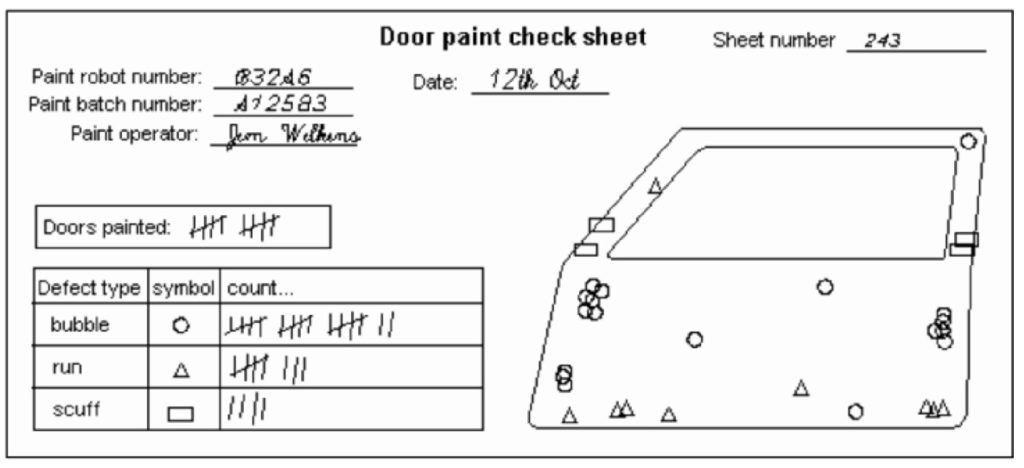

Location Sheet: This usually employs a diagram-based representation of the issues. For instance, one can indicate the damages and dents on a car body by marking the corresponding location in its picture.

|

| Example of Location Sheet |

Graphical Sheet: This is using a graphical form of

representation such that observer can collect data and visualize the

distribution of data.

What is Check Sheet Format?

An appropriately designed check sheet covers various points, such as frequency and location of defect event, whether or not inspections have been completed etc. Some of the common points that usually included in the format of a check sheet are as follows:

- Name of the operator

- Type of the data being collected

- A location where the data is being a collection

- Schedule of data collection

- The objective of data collection

Tips for effective check sheet:

- Make sure that all the operators involved in the process are properly trained, and they clearly understand every section of the check sheet.

- Run a short pilot exercise to validate that the sheet captures the required data appropriately and if required, then make the necessary improvements.

- As far as possible, try to make use of quantitative data instead of qualitative data as the former results in more conclusive evidence.